Defence Manufacturing

Biz@India

June 2016

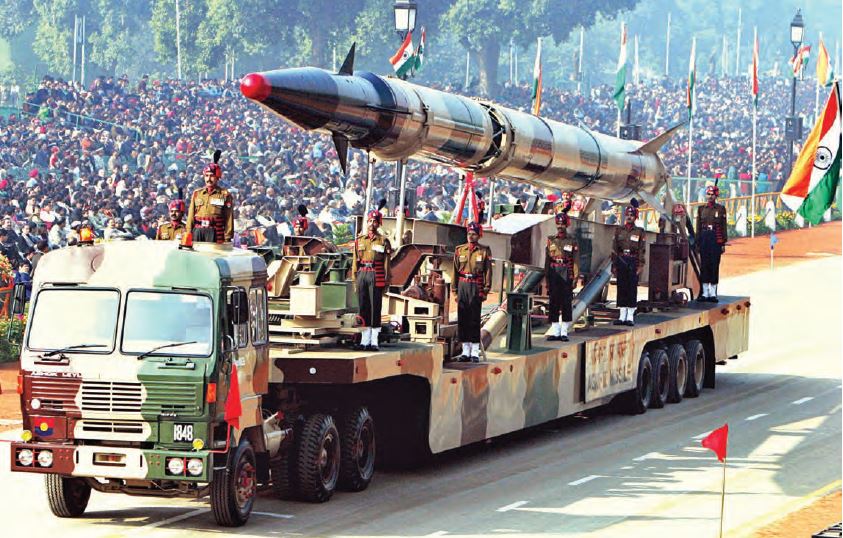

Agni II Missile on Republic Day Parade

‘Make in India’ programme emphasises on defence manufacturing and is the focal point of the budget 2016, making the private players – both Indian and international – the real beneficiaries.

The Indian tycoon and the founder of conglomerate Reliance Group, Anil Ambani, wants to make missiles, helicopters and submarines. His plan is to turn Reliance into a major defence company and he has already bid for INR 840 billion (EUR 11 billion) in government contracts, as per a recent report by the news agency-Reuters. Though Reliance Group is latest in the race, many defence firms are keen to ‘Make in India’. A domestic telecom equipment maker Himachal Futuristic Communications (HFC) is one of the private firms eyeing defence projects. The company has already been granted industrial licences for a range of products which include electronic fuses, electro optical devices and communication equipment along with the permit for assembling electronic warfare systems, radars and design, development and manufacturing of aircraft, including helicopters, says Bela Banerjee, director, HFC.

With more than USD 200 billion (EUR 176 billion) capital expenditure expected in the next 8 to 10 years, and with one of the fastest growing defence budgets in the world at 10 to 11 pc growth rate, India focuses on strengthening defence facilities and building manufacturing capacity. Of late, the government has been on the mission. According to the department of industrial policy and promotion (DIPP), responsible for formulation and implementation of promotional and developmental measures for growth of the industrial sector, the commerce ministry has granted 333 industrial licences to private firms for defence manufacturing, which includes names like Mumbai based Micronel Global Engineers, Kolkata based Naistoco India and OIS Advanced Technology based in New Delhi. There are more familiar names too like, Punj Llyod Aviation, Bharati Shipyard, Ashok Leyland Defence Systems, AMW Motors and then there are big, established ones such as Bharat Forge, Tata Group, Larsen & Toubro (L&T), Mahindra Group, to name a few.

So, the reason for this rush to be part of the defence sector is mostly the result of Prime Minister Narendra Modi’s emphasis on defence manufacturing as part of his ‘Make in India’ campaign. Last year, Modi said that with 60 pc of India’s defence requirements met through imports, local defence production is at the heart of the ‘Make in India’ programme. Launched on September 25, 2014, the idea of ‘Make in India’ is now more than 20 months old.

Private players – the real beneficiaries

According to AK Gupta, secretary, department of defence production, ministry of defence, the private sector now has the opportunity to pick up a 25 pc share of defence production. “Around 25 pc of the defence PSUs (public sector undertakings) turnover can be off-loaded to the private sector, and the ministry has already de-licensed 60-70 pc of the production. PSUs in defence sector have a cumulative turnover of about INR 500 billion,” he said during a conference at DefExpo which took place in Goa in March 2016.

“Under the ‘Make in India’ programme, the government has awarded 56 defence manufacturing permits to private sector entities in the past one year compared with 47 granted in the preceding three years,” says Anurag Garg, director- strategy and defence leader at professional services network headquartered in London, PwC (PricewaterhouseCoopers), adding, “Make in India has become the new mantra in the Indian defence industry and within the industry, private sector is the centre of attraction. This is quite evident from some of the big measures taken so far like hike in the foreign direct investment (FDI) from the earlier 26 pc to 49 pc, streamlining of defence industrial licencing, rationalisation of taxes, etc. Ultimately, private sector is the biggest beneficiary.”

Mcdonnell douglas Fa18 hornet

“In the case of the INR 500 billion (EUR 6.6 billion) P-75I project for procurement of six conventional submarines for the Indian Navy, the Modi government has changed the previous government’s decision to import two submarines, followed by four to be licence-manufactured by public sector shipyards, and decided to construct all the submarines in domestic shipyards, with the further provision that the private sector would be given a fair chance to compete to get the contract,” says Col K V Kuber, independent consultant, aerospace and defence.

In an interview with a defence news portal, Jan Widerström, country head and chairman of Saab (Swedenbased defence firm), said, “Make in India is definitely on our agenda. Our footprint in India is expanding fast. We now have eight Indian partner companies working with us.” Its new fighter jet-Gripen E, which is said to have improved avionics system, is also considered under ‘Make in India’. Not only Saab, but other players like America’s Boeing and Lockheed Martin have also shown interest in making their aircrafts (F/A-18 and F-16) in the country. The opportunity is not only confined to foreign firms but domestic private firms have a significant opportunity, mentions Garg from PwC, adding, “The major players in the space have been investing for the past decade or more like Bharat Forge, Tata Group or L&T and have built a portfolio in electronics, land systems, missiles and aerospace products. Most of these are either in talks or have already signed the deals with the foreign Original Equipment Manufacturers (OEMs).” There were some similar announcements made during the DefExpo in Goa last March. Bharat Forge has tied up with Israel defence tech firm Rafael Advanced Defence Systems, Elbit Systems and UK-based Rolls Royce. Similarly, Tata Group has tied up with US-based firms Sikorsky Aircraft, Lockheed Martin and Boeing.

For more than 15 years, India has tried to engage the private sector in defence production. But domestic defence manufacturing is still dominated by the defence public sector undertakings (PSUs) and the Ordnance Factories Board (OFB), which together command 80-90 pc share. Of late, however, Indian private companies have shown interest in the defence equipment business and have applied for industrial licences from the ministry of commerce to locally manufacture military equipment, including airplanes and warships.

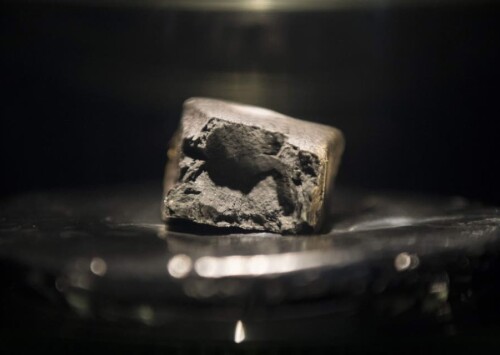

Project 75I-class submarine

A report by domestic brokerage ICICI Securities, published in January 2016, stated that imports contribute almost 75 pc of the defence equipment needs, while public sector and domestic private sector players contribute only 20 pc and 5 pc respectively. “While the growth of the defence sector will follow along its strategic and technological requirements, the domestic defence industry is still in its infancy—which translates into a huge opportunity for investors and Indian enterprises,” the report by the brokerage firm said.

DPP – to boost ‘Make in India’

In April this year, Defence Procurement Policy (DPP) 2016 was unveiled, in which ‘Make in India’ was the key highlight. A new procurement category — Indigenously Designed, Developed and Manufactured (IDDM) — has been introduced and accorded top priority, which means the government is leaving no stone unturned to give a boost to Make in India. The Make in India category has been divided into two categories — ‘Buy (Indian)’, with 40 pc indigenous content, and ‘Buy and Make (Indian)’ having an overall indigenous content of 50 pc, whereas DPP 2013 laid down minimum percentage of indigenous content for each acquisition route, which was 30 pc. “The IDDM and Buy and Make Indian categories will help global OEMs and Indian companies forge partnership for co-development and co-production. The integration of Indian companies in the global supply chain will help the establishment of defence manufacturing,” says Garg from PwC.

The ‘Make’ procedure is divided into two categories – projects under Make I category will involve government funding of 90 pc, released in a phased manner, and based on the progress of the scheme, as per terms agreed between ministry of defence and the vendor. While, projects under Make II category will involve prototype development of equipment or system or platform or their upgrades, or their sub-systems or sub-assembly or assemblies or components with a focus on import substitution, for which no government funding will be provided for prototype development purposes. And it has considered the interests of Micro, Small and Medium Enterprises (MSMEs) too. To bring the MSMEs into the loop, projects with an estimated cost of development of up to INR 100 million (EUR 1.3 million) under the first category and INR 30 million (EUR 395,000) under the second category will be earmarked for them. These projects will be opened to others only if MSMEs do not evince any interest.

Union minister for defence, Manohar Parrikar at the “Global Investors’ Summit-Defence Sector”, organised at the DefExpo 2016, in Goa in March

“The prioritisation of Buy (IDDM) in procurement category and ‘Make’ project is aimed to provide handholding to ‘Make in India’ initiative and has the potential to increase the contribution of manufacturing output to 25 pc of country’s GDP,” says Col Kuber, adding, “With the DPP 2016 in place, it has become increasingly apparent to all concerned that the defence manufacturing capability cannot be built in isolation and requires the active involvement of the private sector.” Boston Consulting Group (BCG) estimates that the defence sector has a potential of increasing the defence-manufacturing workforce by one million people within five years. Every million directed job created in defence manufacturing will create additional 0.5 million in indirect jobs through sub-contracts and vendors.

Looking forward

The government is doing its bit with programmes like Make in India to enhance the industrial capacity and manufacturing facilities of the companies – both Indian and foreign – need to respond to the changes. Garg from PwC says, “To be able to qualify and continue to play in most defence programmes in India, it would be important for foreign companies to have some local presence via transfer of technology, co-development, manufacturing, and for Indian companies to enhance their capabilities to locally design and manufacture. And global OEMs (Original Equipment Manufacturers) need to respond to these changes, by forging relations with large players in Make in India. Though it is happening but still it is not sufficient.”

It is envisaged that under the Make In India programme, at least half of total India’s weapon and equipment needs in the next 10 to 12 years worth more than USD 100 billion (EUR 88 billion) is likely to be produced domestically; so the opportunity is galore. Col Kuber, says, “The government is taking initiative to encourage greater private participation in the defence sector and emphasis on other local manufacturing requirements, opening up the sector for the foreign investors,” adding, “With the global price pressure, India is likely to become a large sourcing base for components and sub-systems thus energising the MSME (micro, small and medium enterprises) sector due to large and relatively low cost engineering talent pool.” With initiatives such as Make in India, India’s dream to be self-reliant in defence production seems more achievable than before!

Current scenario of Indian Imports

India has imported EUR 10.9 billion worth of weapons, aircraft and missiles in the last three years

Source: Makeinindia.com/sector/defence-manufacturing

Some existing foreign investors

• Airbus (France)

• BAE India Systems (UK)

• Pilatus (Switzerland)

• Lockheed Martin (USA)

• Boeing India (USA)

• Raytheon (USA)

• MBDA (France)

• IAI (Israel)

• Rafael (Israel)

Indian Companies in Defence Sector

Mazagon Dock Ltd

Mishra Dhatu Nigam Ltd

Mahindra Defence Systems

Tata Advanced Systems

Ashok Leyland

Bharat Dynamics Ltd

Bharat Electronics Ltd (BEL)

Bharat Forge

Electronics Corporation of India

Ltd (ECIL)

Garden Reach Shipbuilders & Engineers Ltd

Goa Shipyard Ltd

Hindustan Aeronautics Ltd (HAL)

Reliance Defence