MRO

Biz@India

March 2016

MRO, Waiting for Wings in India

With an estimate of 1,200 airplanes in its vault from the current 400 in the next 20 years, India’s aviation sector is poised to grow. However, this growth could be futile if India does not develop the Maintenance, Repair and Overhaul (MRO) sector to match the pace.

On September 25, 2014, Indian Prime Minister Narendra Modi launched a special initiative aimed at encouraging domestic and global players to manufacture products in India. Aviation, which offers immense opportunities for the world, is one of the targeted sectors in the ‘Make in India’ programme. India’s civil aviation industry has been in the thick of action and expansion in the last two decades. Drivers such as low-cost carriers, modernisation of airports, FDI, high- tech and digital interventions, no-frills airports and a growing emphasis on regional connectivity have propelled India as the ninth-largest civil aviation market in the world, with a market size of approximately USD 16 billion.

No wonder, Tony Tyler, director general and CEO, International Air Transport Association (IATA) had observed, “The world is focused on Indian aviation – from manufacturers, tourism boards, airlines and global businesses to individual travellers, shippers and businessmen.”

MRO sector: At nascent stage

India, with its growing aircraft fleet, strategic location advantage, rich pool of engineering expertise and cheap labour cost has huge potential to be a global Maintenance, Repair & Overhaul (MRO) hub in the long term. Yet, India has been unable to do so.

According to estimates by leading global aviation player Boeing, the size of the Indian MRO stands at about USD 700-800 million (INR 47-54 billion). This figure is expected to grow at 7 pc CAGR (compound annual growth rate) over the next six years to reach USD1.2 billion (INR 80 billion) by 2020, it reported.

Buoyed by the bright prospects that India offers for MROs, aviation players in India spend about 13–15 pc of their revenues towards maintenance. The MRO sector comprises of airframe heavy maintenance and modification, engine maintenance, line maintenance and component maintenance.

This is the most important expenditure in the aviation sector for airlines after aviation fuel. While airlines generally carry out in-house and on-tarmac inspections themselves, the carriers work with third-party MROs for engine, heavy maintenance and modifications.

The lack of access to aviation services for as much as 97 pc of the population is an opportunity waiting to be tapped by India’s aviation sector. The sector, including MROs, is set for an exponential growth as the current scenario represents tremendous scope for expansion of MRO facilities in India. Currently, India has 400 commercial and 700 general aviation aircraft.

A study done by multinational auditor PwC (PricewaterhouseCoopers) on the Indian aviation sector cited wages in the sector, ranging from USD 35 to 45 (INR 2,344 to 3,014) per hour, as a key positive. “It (Indian aviation sector) has a robust supply of talent, available at relatively cheaper rates and a large and able population of engineering graduates. India also has over 55 aircraft maintenance training schools to ensure a steady supply of suitable talent,” it noted.

“The Indian MRO industry has the advantage of a large market, and lower cost and easily trainable manpower,” observes another industry analyst Amber Dubey, partner and head (Aero- space), KPMG.

No wonder then that a FICCI-KPMG report pegged India to become the third largest aviation market by 2020 and the largest by 2030.

MROs in India

The MRO infrastructure in aviation sector in India is largely captive with Air India. The only fully operational independent third-party provider MRO is Air Works located in Hosur near Bengaluru. Established in 1951 and operational in 10 countries, Air Works recently bought a minority stake in Irish firm Acumen Aviation Europe Ltd, which provides services for airlines and aircraft leasing companies. MROs play an essential role in the Indian aviation sector as every aircraft undergoes mandatory periodic checks ruled by the regulators. However, India’s efforts in setting up MRO services are not only nascent but have also been fraught with some practical difficulties.

Key challenges

MRO is a highly capital-intensive industry and requires a long gestation period and huge investments from do- mestic as well as global players. It also calls for greater need for continuous investment in tooling. Global certifica- tion from safety regulators such as the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA) is also required. Global Original Equipment Manufacturers such as Airbus, Bell Helicopter, Boe- ing, Bombardier Aerospace, Dassault Aviation, Gulfstream Aerospace and Honeywell – all play a key role in bring- ing technology and investment.

Certification from the directorate general of civil aviation (DGCA) is also required. Moreover, land shortage in airports and the lack of clarity in land allotment prevent potential MRO players from coming into their own. However, this has been resolved by reserving land for MRO activities at newly built international airports in Bengaluru and Hyderabad.

India has accorded ‘in-principle’ approval for setting up15 greenfield airports in the country. Yet, the MRO service, which is an essential requirement, has not been factored as part of the airport infrastructure. Even lease of hangar space into MROs at various airports in India is a complex issue. Availability of land, customs and immigration clearance are other issues that MROs need to contend with.

As a result of these challenges, airlines operating in India are forced to service their aircrafts outside the country. “As of now, it is heavily dependent on imports. Everything is imported, including servicing of aircraft. If you look at airlines, except Air India, all other airlines are going out of the country for their routine checkups. They are going to Singapore, Dubai and Sri Lanka. So, we need to pull in that USD 700 million business into India,” asserted India’s civil Aviation Minister P Ashok Gajapathi Raju, while addressing a seminar – Make in India: Challenges and Opportunities in Civil Aviation Sector – organised by the Foundation for Aviation and Sustainable Tourism (FAST) recently.

Setbacks

That’s the ground reality. Take the MRO facility at Multi-modal International Hub Airport at Nagpur (MIHAN) built at a cost of USD 100 million (INR 6.7 billion) by Boeing as an example. The facility, which was inaugurated by union transport minister Nitin Gadkari in June last year has failed to make progress. The MIHAN facility came up as a result of an agreement between state-owned Air India and Boeing after the national carrier placed a massive order for Dreamliners with Boeing in 2006.

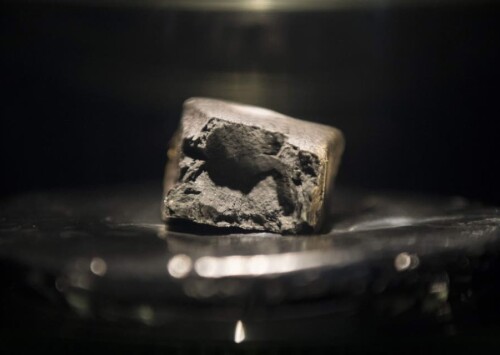

The MRO facility at Nagpur airport between Air India and Boeing has so far received two Boeing 777 aircraft

So far, the facility has only received two Boeing 777 aircraft – the first in May 2015 and the other in February this year. Surprisingly though, Air India has decided to give up its state-of-the- art MRO facility in Nagpur after it was unable to convince its engineering staff to relocate. Last month, the national carrier – Air India invited bids from private players to run the facility.

Another setback came in the form of Toulouse-based French Airbus, the world’s leading aircraft maker that was also planning an aircraft MRO facility in India on account of large orders from both national and private carriers. However, delayed deliveries by Airbus have resulted in the MRO facility taking a backseat for now.

It is for these reasons that Indian carriers are forced to look at MRO centres that are located in South East Asia, Middle East or Europe, resulting in huge expenses to ferry flight, logistics costs and engine/component hours. Besides, there are 40 overseas MRO providers approved by the DGCA to conduct work on Indian registered aircrafts in locations such as United Kingdom, Germany, France, Jordan, UAE, Sri Lanka, China and Singapore amongst others.

Flying out

IndiGo – India’s low cost carrier that operates a fleet of more than a hundred A320ceo (current engine option) aircraft has been availing service from Colombo in Sri Lanka since February 2009. In February 2016, the carrier selected Singapore-based UTC Aerospace Systems’ aerostructures unit to provide nacelle asset support and MRO services for the airline’s fleet of new Airbus A320neo (new engine option) aircraft. MRO support for IndiGo will now be provided at Goodrich Aerostructures Service Center-Asia Pte Ltd. in Singapore. Similarly, other aviation players also fly to foreign destinations to avail MRO services.

“The domestic players are not coming to Indian MROs because it is 30 pc costlier as compared to MROs abroad. Delhi, Bangalore, Hyderabad and Mumbai have major MRO facilities. At present, state value added taxes range from 12.5 pc to 17 pc making the sector highly uncompetitive in South Asia. Indian MROs end up paying 15 pc of service tax and 29 pc customs duty on consumables imported apart from the hassles of importing them. With such tax structures how can India emerge as an MRO hub if there is no level playing field?” asks RN Johri, chairman and managing director of Aman Aviation & Aerospace Solution Pvt Ltd, a Mumbai-based MRO company.

Pulak Sen, secretary general of the MRO association of India, echoed similar concerns. “The taxation issue acts as a deterrent. We need to understand that the aircraft parts are universally priced,” he said. Now, state- run Pawan Hans Ltd, which specialises in helicopter services, is planning to set up four MRO firms as a part of its diversification plan. It is also India’s largest helicopter operating firm that is exploring an initial public offer (IPO).

“Pawan Hans is setting up MRO centres at two places in New Delhi and at Juhu airport in Mumbai. And then we have a plan to extend it to other parts of the country in Northeast at Guwahati and one in southern region. Presently there is no MRO facility for helicopters and it’s a big business. We are coming forward with this. The ‘Make in India’ initiative of the government also supports this. This will also create a lot of job opportunities for pilot and aircraft engineers,” said Dr B P Sharma, chairman and managing director, Pawans Hans Ltd.

Why India needs a strong MRO facility?

Currently, India’s share in the global MRO business is merely 1 pc. As aviation is set to witness robust growth, a strong MRO can generate employment for Indian engineers, boost the country’s MSME (Micro Small and Medium Enterprises) sector, reduce the service dependency of Indian carriers on outside locations and consequently, save and earn foreign exchange by attracting national and global players to Indian MROs.

Despite several favourable factors, India’s stiff tax regime has been a major factor holding back the growth of MROs for many years. However, things have begun to change; though slowly. In 2012-13, the then finance minister Pranab Mukherjee had waivered customs duty for import of spares and testing equipment by MROs. However, the duty waiver could be availed only if the spares were utilised in three months. In the Union Budget presented for 2013-14, finance minister P Chidambaram modified that condition by extending the duty waiver period to a year.

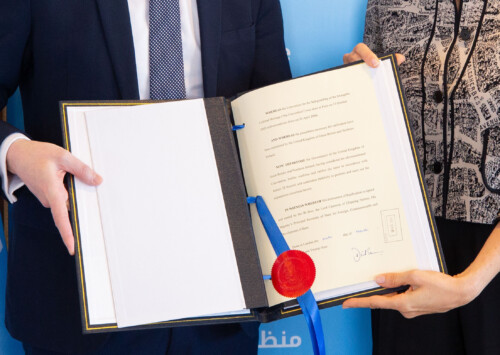

With India emerging as the fastest growing economy amidst global slowdown, it is making the right noises in terms of improving regulatory architecture, tax framework and pursuing economic reforms. Consequently, the revised draft of civil aviation policy promises measures to boost the sector, including MROs. In keeping with this promise, current finance minister Arun Jaitley also made some suitable announcements in the budget for 2016-17. These measures include changes in customs and excise duty structure to incentivise domestic value addition towards ‘Make in India’ campaign – something that the government expects will reduce costs and improve competitiveness of domestic industry in sectors including MRO.

Civil aviation minister Gajapathi Raju hailed the budget presented by his cabinet colleague and asserted how it has paved the way for developing India as the MRO hub of Asia. Explaining the impact of the budget proposal, Raju listed half-a-dozen ramifications that will affect the MRO sector.

Amongst the incentives listed by him are customs and excise exemption for tools and tool kits used by the MRO industry; certification of exemptions by the sector regulator to ensure expert oversight and simplification of norms for exemption. The minister also highlighted how restrictions over using exempted parts within one year have now been removed and import of unserviceable parts by MROs have been allowed. Duration of stay for foreign aircraft brought to India for MRO has also been extended to six months. The aircraft can carry passengers in the flights at the beginning and end of the stay period in India.

Looking ahead

While most industry players have welcomed the budget proposals, they want more. “In this budget, they have facilitated the process of import of sales. For an MRO, two factors are important. Efficiency and turnaround time are very critical for an aircraft. All these are huge value additions for creating efficiency in the MRO,” said Ravi Menon, executive director of Air Works. Similarly, welcoming reforms in the MRO sector in terms of duty free period for parts and removal of customs duty on tools, Johri of Aman Aviation & Aerospace Solution, wondered why a bigger relief in terms of zero rating of service tax, infrastructure status, easing out the customs procedure and zero duty on consumables have been left out.

“If this custom duty is imposed on the import of MRO services, it will give nearly USD 285 million (INR 19 billion) as revenue that will be around 30 pc of the USD 985 million (INR 66 billion) worth of MRO services currently imported without any duty. Today, the government is only collecting USD 7.5 Million (INR 502 million) as 15 pc of USD 50 million (INR 3 billion) worth of MRO services done in the country forms a part of the service tax,” Johri said, batting for the government too.

India’s airline fleet is set to grow to 1,200 airplanes from the current 400 in the next 20 years. As a result, local MRO companies are eyeing a business opportunity of USD 1.5 billion (INR 100 billion) by 2023.

MRO sector in India is still an emerging industry and needs to evaluate and identify the efficiency that needs to be created going forward. This, many believe, is an on-going process. As one industry veteran recalled, we must remember that Rome was not built in a day. Given the bureaucratic challenges, if things are not rationalised or ratified today, it sure will be done in a year or two. Hope it is not too late by then.