Interview: Robert Jans – Director, Ekolog India

Biz@India

December 2018

Robert Jans, Ekolog’s India director

Ekolog, a Polish solid waste and sewage management and renewable energy equipment firm has undertaken key projects in India. Robert Jans, Ekolog’s India director, talks to Biz@India about their technological innovations in the waste management industry and other projects in the country.

What have been the key landmarks in Ekolog’s journey?

Ekolog has been present in the market since 1983. It was one of the first private companies in the environment protection sector in Poland. Its core specialisation is wastewater treatment and sludge management. The major landmarks in this field were the construction of wastewater treatment and biogasification plants in Torun and Gliwice in Poland, Shymkent in Kazakhstan and Ivano-Frankivsk in Ukraine. Those plants were – and in case of Shymkent still are – one of the biggest and most modern plants in the region. In the field of solid waste management we have been active since early 1990s. We have participated in creating the system for Poland and executed several significant contracts at that time. After an interval of a few years along with development of technology of cofermentation (biogasification) of wastewater sludge and organic waste, we came back to the search and execution of solid waste projects, mainly in the export markets, currently Ukraine and India.

How is the situation of waste management in Poland? What is the market share that Ekolog has in its home country?

Waste management in Poland began to change from the early 1990s. Since then, laws and other regulations, including the financial support system, regulating modern waste management systems have been implemented. The current system is based on the division of the country into regions in which waste is collected selectively under the ‘at source’ segregation system and transported to Regional Treatment Plants. Collection and transport is handled by private companies that conclude contracts with the Cluster of Municipalities. Processing plants (currently 186) belong to City or Cluster of Municipalities and operate in the form of Municipal Owned Companies. There are no DBFO or BOOT projects in the waste management sector in Poland. All projects are financed by the Cluster of Municipalities. The goal of each plant is to maximise the recovery of recyclable materials, the production of organic compost and the minimisation of dump waste. The entire system is already fully active and meets the requirements of the European Union (EU). Currently, every year, a new technological and organisational solution is implemented, focused on achieving the highest level of materials for recycling.

Ekolog was also involved in the construction of a new waste management system since the early 1990s. At the beginning of this period, together with companies from the US and Western Europe, we developed the organisational and technical base for the construction of a regional system. Since then, we have completed dozens of technological and organisational projects for the waste treatment plants.

Is your technology patented/unique or is it generic to the waste management industry?

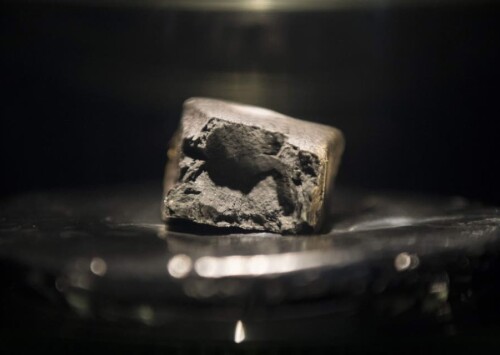

We have developed own technology during last 20 years and also upgrade it regularly to be more innovative. Our latest technologies, ANADI Sludge – anaerobic digestion of sewer sludge and ANADI Organics – anaerobic digestion of organic fraction from MSW, were developed under an EU programme for developed innovative processes. Another of our technologies, BIOSort AD, is dedicated to separate clean organic material from mixed stream of municipal waste to later process ANADI. All technologies are unique and protected as company ‘know-how’.

Which have been your major projects in the developing nations? What is the source of financing these projects?

The major export markets in which Ekolog has been successful are Ukraine and Kazakhstan, where we’ve been present for 10 years. All projects are financed by the host country governments, local municipalities as well as by long-term loans from World Bank.

What is the solid waste management plant that you will set up in Kempegowda International Airport (KIA) in Bengaluru? What innovations will you be implementing for the solid waste management project? How is this financed?

The waste processing plant, which we designed for the international airport in Bengaluru, complies with the highest global standards in the field of deep waste segregation and high-efficiency biogas installations that will be used to produce electricity. The plant after reaching full capacity will produce more electricity than it consumes and the surplus energy will be sold to the BIAL internal network. The plant’s technology is based on two of our innovative technologies. According to our knowledge, this is the world’s first waste management installation that will operate at an airport. The project has been entirely financed by us.

What are the latest technologies that you use in converting organic waste to energy?

On fermentation and co-fermentation of wastewater sludge and liquid organic waste, we have been working for 20 years and till now we’ve designed and/or built 13 biogasification plants. Since 2016, with the financing from the EU, we have developed highly efficient and advanced technology in this domain. It is based on longterm experience and very good understanding of waste structure and methane fermentation process. The output is biogas that can be used for making electricity and heat. The end product, which remains after fermentation, is a pure and high quality city compost or fertiliser.

Our process generates 35 pc more biogas (and in consequence a power) than the conventional biomethantion process used in typical biogas plants.

Last year you teamed up with JBM group for operating a 5 MW power plant that would treat 500 tonne of municipal waste. What is the progress on that?

The project is at the design stage and in-depth economic analysis. The beginning of the investment is expected at the beginning of 2019.

Are you coming up with any other projects in India? How do you evaluate the situation of waste management in India?

We cooperate with several leading companies from the waste sector in India as a technology provider. We are currently involved in five different projects that are still in the tender phase. The model based on private financing, adopted in India for the construction of Waste to Energy (WtE) plants, is slowly running out. The inability to generate external financing, the delaying or even reluctant attitude of banks in India for this type of projects, limits the possibility of further participation in such tasks.

Targeting only on waste incineration in order to recover energy effectively eliminates the interest of European and American companies that generate income from waste processing in a different way. Companies that offer typical WtE plants from Europe are also not interested in the Indian market, because their technologies are much more expensive and the energy rates offered do not allow for the expected return on investment.

The possibility of wide opening to the construction of a large number of regional waste management facilities may be opened by utilising other directions for the processing of waste as: concentration on the recovery of secondary raw materials, biomethanisation processes for biogas production, production of alternative fuels for cement plants and power plants.

In addition, there should be a change in the financing of projects through increased participation in the support of local governments and the central government, by general introduction of a tax. It should be understood that waste is a social problem and not a ‘private business’. It is just as important as the production of drinking water or wastewater treatment. It is not understandable for western companies, in view of the social model there, why waste problems in India have been ‘pushed off’ by the financial possibilities of the private sector. This is not a viable solution for a long-term solution to the waste problem.

How much are you investing in the KIA project in Bengaluru as well as in the Sonepat cluster project?

The investment expenditure for KIA project is approximately EUR 2.5 million. Deep segregation system and biogasification of organic waste for Sonepat project require investment of approximately EUR 7 million. The financial engineering for both projects assumes minimal own contribution and external sources of financing, both public and private.

Do you adapt your technologies to local conditions or are these one size fits all?

It is not possible to transfer ‘copy-paste’ solutions from Europe to India. In this solution, the investment cost would be 3-5 times higher than market expectations. Our technological solutions have to be adapted to local conditions. Of course, the main technological process remains the same, but the equipment used should be obtained as much as possible from producers in India. Also, climatic conditions enforce some modifications such as to the biomethanisation process. It is therefore necessary to adapt our solutions in a way that preserves the modernity of technology.

What do you think India lacks when it comes to solid waste management and what can it do to be a step ahead in clean technology? Are you looking at jointly developing some technologies in India with a local partner?

The most important barrier is the method of financing investments based on private sources. This has led only the largest companies, with a strong equity position, to be active in India. Recent months show the problems of very large companies such as IL & FS, JINDAL or Ramky indicate the exhaustion of this model. Over 200 companies are active in Europe in the industry, while in India, a comparable area, only a dozen or so. This shows how narrow the possibilities of the industry are.

A separate aspect is the lack of projects for smaller towns, where the size of the plants is at the level of 150- 300 Tonnes Per Day (TPD). This is the basic size for plants in Europe and they have the greatest impact on waste management for the communities. So what, if we build a plant for the largest cities, while still 80 pc of the population lives in the garbage still!

Another aspect is to rely solely on waste incineration technologies to recover energy. There is no interest in other technologies used in the world that perfectly complement or solve the waste aspect – in particular the recycling of inorganic waste and the processing of organic waste.

We always work with local partners on international markets. They know the local conditions best and they are the ‘hosts’ of the market. Ekolog as a technology company can only be a partner and supplier of technology.

Did you face any challenges in working in India?

Of course! For four years of our intensive work in India, we have recognised a lot of cultural differences, customs, language specificity, time difference and many, many more. Our representatives in India, in New Delhi and Bengaluru, are a huge support for us in this area. The challenge is almost always to contact with representatives of various state or government institutions, whose representatives often ‘emphasise’ their validity in procedures. This extends the deadlines for arranging various types of permits, certificates, admissions etc. We are happily dealing with this phenomenon so far.